Revolutionizing Conservative Treatment

CAD/CAM restorations can optimize your productivity - here’s proof.

CAD/CAM technology is revolutionizing conservative treatment. This may surprise you, because CAD/CAM systems are still considered by many dentists to be a major capital investment. Nevertheless, this erstwhile emerging technology is rapidly becoming a must-have piece of equipment - an everyday, every patient treatment modality. In fact, CAD/CAM technology is revolutionizing the way the dental industry provides restorative services, from sole practitioners to multi-chair to multi-office practices, including crowns, onlays, inlays, veneers, and implants.

That’s because CAD/CAM technology, such as the CEREC 3, is not only enabling dentists to operate more efficiently and cost-effectively, it’s also taking elective, cosmetic dentistry from the so-called rich and famous and bringing it to the “average Joe.”

The fees associated with many restorative procedures have traditionally been beyond many patients’ means as a routine treatment choice. The battles with insurance coverage for onlays, and the frank denial of coverage for inlays leave many patients wondering if there are other choices.

The choices most dentists are left with are either crowns or fillings. The only significant changes in these traditional treatments have been the material choices. For example, all-ceramic crowns have replaced porcelain-to-metal, and direct-placement composites have replaced silver alloy.

Accelerating alloy-to-composite conversion

Many doctors are proud to say they’ve stopped using alloy in their practices for any treatment. They are aware that direct-placement composites have improved over the years. They also are aware that they are time-consuming to place, are technique-sensitive, and rarely result in the quality of restoration we seek.

This is especially true in the case of posterior composites, when the size of the existing failed restoration and/or decay is substantial enough to break the contact buccal-lingually, and is greater than 3 mm occlusally and proximally. Another example of a less-than-optimal solution is when dentists choose direct-placement composites for restorations involving three, four, and even five surfaces.

Our ability to consistently and predictably create restorations with the correct occlusal and gingival embrasures, marginal ridge placement and contact areas, and occlusal morphology is complicated by the nature of direct-composite materials. We all know this to be true because of the never-ending variety of adjunct “techniques and tips,” as well as material changes and improvements written about every year. With alloy it was simple - a Tofflemire matrix band, a tight wedge, and push hard - then just hope everything didn’t break when you carved it.

With few exceptions, dental schools continue to teach this technique because of its simplicity, predictability, and low cost. But alas, this is not the way of the world. All dentists learn to handle posterior composites on their own.

My personal journey with this dilemma started in the early 1980s with one of the first laboratory-processed ceramic techniques for the fabrication of all-ceramic inlays and onlays, called Mirage. I continue to see patients with Mirage restorations in place and functioning. Even though there was no such thing as dentin bonding, the concept of a bonded indirect ceramic restoration was established. At that time, the predictability of the indirect laboratory process was inconsistent. In addition, the cost in chair time, materials, and associated lab fees forced us to charge higher fees. This was consistent with our thinking about the quality of gold inlays and onlays, and gave us an alternative for those patients who did not choose gold display.

Today, this alternative exists in a variety of laboratory-processed ceramics starting with Empress. Yet, by a wide margin, most dental offices continue to offer and treat teeth with fillings (direct-placement composites) and crowns (laboratory-processed).

The CAD/CAM cost paradigm

What if we had a technique to fabricate a precision-fit restoration out of resin that was so efficient that we could charge a direct-placement (composite filling) fee? Would that be considered a radical change in dentistry? Just think of it - being able to create contact and embrasure form with a material that lasts, is easy to adjust and polish, and cost-effective for you and your patients.

We all recognize that this cannot ever be accomplished using an indirect technique that requires impressions, temporaries, and second appointments. So why is it that I continue to read about indirect, laboratory-processed, resin-based restorations? We should all know the following by now -

→ Resin-based materials cannot be billed to insurance using a ceramic code (that is fraud).

→ The cost of this process precludes charging a direct-placement filling fee.

The answer to this dilemma is to use a CAD/CAM system such as CEREC 3D to fabricate your resin fillings. If you are asking how it’s possible to get a return on your capital investment by charging (filling) fees, the answer is really quite simple - efficiency!

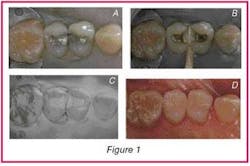

When we measure productivity in a dental practice, we are really evaluating how efficiently the doctor is working. For example, to place direct composites, the doctor needs to be with the patient the entire time. When we use our CEREC 3D, I only need to be with the patient to prepare the teeth, and then return to seat and finish the restorations. The optical “picture” of the preparations (replacing traditional impressions) can be taken by my trained dental assistant. The design, milling, fitting, and preparation of the restoration for bonding also can be accomplished easily and efficiently by trained staff.

CEREC 3D software in its current configuration is easy to learn and efficient to use. The ability to “correlate” or copy the existing occlusion is so accurate that there is little to no adjustment necessary after bonding the restoration to place. This is a huge time savings when compared to the “overbuild-and-grind-it-in” scenario necessary with direct-placement composite fillings.

The quadrant modality allows me to prepare several teeth at once. We can image and construct a virtual model of the quadrant. Our staff member can design one restoration and virtually seat it before starting the milling process. She can then return to design the adjacent restoration against the previously “virtually seated” restoration. This keeps the occlusion, contact and embrasure form consistent throughout the quadrant and minimizes the delivery and adjustment time. These built-in efficiencies allow me to do “dentist-necessary procedures” while my staff completes those procedures they are qualified to complete.

Meanwhile, I’m producing elsewhere. Upon my return to the original patient, the restorations are seated using one-step 3M ESPE Unicem. The final finish and polish is achieved quickly and efficiently because -

√ we are using a resin block (3M ESPE Paradigm);

√ it fits;

√ the contours and contacts are perfectly designed into the restoration. The sequence and associated production is represented in Figures 1 and 2, respectively.

For those of you who are unfamiliar with CEREC 3D and the materials available for milling, there are two ceramic blocks and one resin block -

- VITA: Mark II and TriLuxe, feldspathic

- Ivoclar Vivadent: ProCAD, Leucite reinforced

- 3M ESPE: Paradigm MZ100 resin.

The material studies concerning the wear, longevity, marginal integrity, color stability, etc., for all three blocks are readily available. What they show is that Paradigm compares very well and is a very good material.

Performance and appropriate fees

When we consider this information in context with what we know about the ability of the CEREC 3D system to deliver highly accurate, morphologically correct restorations in a time-efficient and cost-effective manner, we can easily conclude that this restoration is far superior to any direct-placement composite filling. CEREC technique and materials have been intensely studied for the past two decades. With more than 200 studies and papers written since the introduction of CEREC technology in the mid 1980s, it is one of the most researched restorative methods. The fit, wear, and longevity of the overall result have been consistently shown to compare favorably with the best laboratory-produced restorations. Fit is well within ADA specifications. These materials show a 96 percent success rate over nine years. And, there is zero postop sensitivity! So let’s use the best materials and techniques to produce the best restoration we can in a cost-effective manner, and pass the savings along to our patients. Is that such a revolutionary concept? I think it is what we have all been looking for but have been unable to achieve with conventional restorative materials and techniques.

Working with insurance companies to offset the cost of restorations by taking the chairside CAD/CAM approach, we have eliminated the wrestling match with insurance coverage. We generally bill this procedure using composite filling codes because Paradigm is a composite material. In this way, we are able to offer our patients a superior restoration for the cost of a filling.

It should be noted that our office files claims exclusively with Washington Dental Service, which is a Delta program. We do not participate in any PPO agreements. We have found that the maximum fee allowed for composite fillings is considerably higher than the fee charged by most practices. Thus, it is important that you take advantage of the highest fee allowable if you file your fees. You are providing a service that is far superior to direct composites, so it is important that you receive a fee that reflects that benefit.

In many cases, the insurance company downgrades the reimbursement to reflect an alloy rate and the patient is responsible for the difference. Our experience is that our patients readily accept the difference when told of the benefits, experience the process, and see the results of a CEREC restoration.

For those of you looking for a better solution to offer your patients with moderate-sized, failing silver alloys (or decay) that are not appropriate for onlays or crowns, a chairside CAD/CAM such as the CEREC 3D can provide the superior, cost-effective restorations you want to offer your patients.

Dr. Mark DiRe has been in practice in Bellevue, Wash., for 29 years with an emphasis on technology and the advanced general practice. In addition to his general practice, Dr. DiRe is a CEREC trainer for Patterson/Sirona at its facility in Seattle and offers advanced CEREC integration courses. Reach him at [email protected].