Technology in the dental laboratory - How it affects the general dentist

The explosion of new dental technologies and materials in recent years is staggering. More dental laboratories are now offering CAD/CAM technology, bringing a paradigm shift to the dental profession. It seems the days of the lost-wax technique are fading fast. But, as the option of all-ceramic restorations has become more and more viable, the choices have become numerous. Differentiating between milling units and materials and then choosing the best option for your practice can be overwhelming. Nevertheless, the rewards this new technology brings are great, so much so that one feels secure in welcoming the metal-free era of restorative dentistry.

For years, patients have been asking for more esthetic restorations. Now, as old unesthetic restorations reach the end of their functional lives, dentists are able to replace them with more versatile all-ceramic crowns, bridges, and inlays/onlays. The dentist no longer has to worry about exposed metal margins. The biocompatibility of these all-ceramic restorations is also improved over the traditional metal-ceramic option. No metal means no risk of galvanic current, no gingival recession as a result of a gingiva-metal reaction, and no thermal conductivity discomfort. The dentist also can focus on conservation of tooth structure as the all-ceramic, esthetic inlays/overlays replace the need for complete crown preparation because of esthetic considerations. The all-ceramic option clearly offers advantages that traditional porcelain fused to metal could never give.

The time to begin the process of going metal-free has come upon the dental profession. The patients are asking to have their old restorations replaced with something more esthetic and biocompatible (Figures 1 and 2).

Significant upgrades in CAD/CAM and related technologies have come in the last 10 years. Most recently, the 3-D topographical software for CEREC inLab is simply stunning, and allows for extremely accurate milled occlusions. The 3-D software will build the restoration’s occlusion based upon a simple bite registration. The porcelain also is now available in many more shades. The Vitapan Classical (Lumin) shade guide only offered 12 shades (i.e., 1A, 2A, etc.), while the VITA 3D-Master extends that number to 80 shades through the mixing of two dentine powders by volume. This increase in shades greatly enhances the dentist and laboratory technician’s ability to match the esthetic needs of each patient. Another significant upgrade involves the development of yttrium-stabilized zirconium oxide, a ceramic material capable of incredible strengths (up to 900 MPa). Such strengths enable the development of all-ceramic anterior and posterior bridges. This new ceramic also is helpful when placing margins subgingivally, as the Fuji I autocure glass ionomer can be used to cement them in the presence of crevicular fluid. Furthermore, there is no need to change your preparation technique because the CAD/CAM restorations accommodate both shoulder and chamfer preparations.

As esthetic concerns continue to dominate the patient’s willingness to accept dental treatment, choosing the proper and desired shade is of ultimate importance. No patient really cares whether his or her amalgam filling matches their metal crown, but porcelain restorations are expected to match. If the patient has opted to whiten his or her teeth, this is obviously done prior to restorative treatment.

Digital shade selection

Digital shade selection devices, such as the Vident Easy Shade, have increased the accuracy of shade selection. By centrally locating the unit in the office, only one unit is necessary. This designated area can serve other duties, such as digital photography and panoramic radiographs. To verify the shade visually with shade tabs, the room can be painted a neutral blue, as recommended by Kodak. Color-corrected fluorescent lighting also is helpful because it eliminates the problem of metamerism. Our porcelain laboratory has been similarly painted and equipped.

It has never been easier to communicate with the patients and the dental laboratory. Computers are now in the dental office and laboratory. Once a desirable shade has been selected digitally, pictures of intraoral shade tabs and preparation shade can be e-mailed directly to the laboratory, where the laboratory technician can select a matching porcelain shade. Once the die has been scanned and the restoration designed by the 3-D imaging software, the restoration can be fabricated. It can be completely milled from a TriLuxe porcelain block, or a coping can be milled from either the VitaBLOCS Mark II or yttrium-stabilized zirconium oxide porcelain block. Dark underlying restorations are blocked out using Vita Effectliner. The wide range of available porcelain shades is then mixed by a trained laboratory technician and stacked onto the milled coping until the custom, shade-matched, all-ceramic restoration is complete.

CAD/CAM fabrication options

The peer pressure to provide one-appointment crowns is there. Your long-time patient sits in the chair and says, “My neighbor went to his dentist yesterday and got his permanent crown the same day. He did not have to wear a temporary. Remember my last crown and that temporary that fell off before my daughter’s wedding? Can you make a one-day crown? Oh, by the way, I want one that does not have that metal up by the gum line.”

For the dentists who are reluctant to spend $100,000 on a CEREC CAD/CAM unit but would like to offer milled porcelain restorations (inlays/onlays, crowns, and bridges) with a quick turnaround time, there is CEREC inLab. This method provides an excellent opportunity for the dentist to sample the future of dentistry, which will include electronic impressions and electronic models that could be e-mailed to the lab.

Beyond expedient and esthetic dental care, these units offer more and less-obvious benefits. Some dentists are using offshore labs more frequently to reduce costs, but these labs do not have our regulations for materials and sterilization. Many discerning patients also appreciate having their work done locally. The rising cost of gold alloys has made the use of nonprecious metals more attractive as a cost-reduction strategy. The shortage of certified laboratory technicians also is troubling and, when they are found, the labor costs can be quite high. The CAD/CAM inLab system meets all of the aforementioned needs. It reduces costs by avoiding the use of precious metals, nullifies the esthetic and allergic issues of nonprecious metals, and satisfies the need for trained lab technicians at a fraction of the cost, all while keeping dentistry within our borders.

Find a local dental laboratory with an inLab unit or other CAD/CAM system, and work closely with them. Even though CEREC inLab is a laboratory-based unit, fully contoured single crowns can be fabricated and cemented within three to four hours. The only additional time required when using the unit is that utilized in taking impressions, delivery times to and from the lab, and the setting time (10 to 12 minutes) of the fast-set CAM-base dental stone. The patient can leave the office, saving you chair time, and come back later that day for cementation.

The inLab indirect method provides a significant advantage over the single-appointment, full-contour restoration. Patients have complained that the nonglazed, milled restorations are not as smooth as their natural teeth. The dentist can rely on the experienced laboratory technician to glaze and stain the restoration.

Complex cases and magnification

Complex cases and magnification

For more complex cases involving multiple units and different restoration types, such as inlays, crowns, and bridges, give the laboratory as much information as possible. Taking full-arch impressions and using a facebow will save you seating and adjustment time at the delivery appointment.

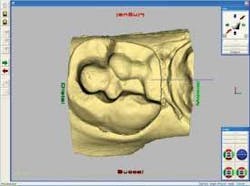

Find a lab that is using magnification. Laboratory microscopes greatly increase quality. The new digital laboratory scanners, such as the inEos lab scanner, an integral part of the CEREC inLab system, allow for full-arch coordination of CAD/CAM copings, inlays, and crowns. The technician views all these preparations at 20 to 40 times magnification (Figure 3).

Quadrant dentistry is more rewarding to the dentist both monetarily and mentally. The new CAD/CAM technology provides an exceptional esthetic quadrant restoration, allowing for porcelain inlays, crowns, and bridges (Figure 4).

null

The time has come

Patients no longer need to have the metal islands or metal second molars. The problem of “mismatching” the shades and esthetics of restorative materials seems to be solved.

Many different kinds of restorations can be done using the same porcelain. The entire quadrant can be restored with matching materials.

Laboratories have always complained that there is just not enough reduction on preparations. The answer is to use reduction guides with a good working knowledge of occlusion, coupled with comprehensive examination and diagnosis.

Continuing education offered by the Pankey Institute and the Dawson Center and other fine hands-on training centers is very helpful in developing the skills to fully diagnose and restore mouths to proper health and function.

The time has come for you to take action - for the good of your practice and for the good of your patients. Find a suitably equipped dental laboratory and work closely with them. If your local dental laboratory does not have a CAD/CAM system, they can outsource to a laboratory within their network.

Pick a system and stick with it. The choice of one system of materials such as Vident, Ivoclar Vivadent, and others will simplify the transition to metal-free restorations. The question is no longer if CAD/CAM technology will affect your practice; it is only a matter of when and to what extent you choose to embrace it.

Dr. Warren Jesekhas been practicing general dentistry in Decatur, Ill., since 1979 and is an L.D. Pankey alumnus. Unique to the area, his practice houses a crown and bridge laboratory with three technicians. He also is an active dental educator through Jesek Seminars and is available to speak on restorative dentistry, occlusion, and temporomandibular joint disorders. Additional information can be found at Jesek.com. Contact him by e-mail at [email protected] or by phone at (217) 864-4494.