Revisiting precision implant impressions can be a time and money saver

Joseph J. Massad, DDS

Welcome back. This month’s tip addresses a concern of many dentists who have experienced frustration with fixed dentures, milled bars, and/or custom abutments not fitting properly, and then being charged for remakes. Several dentists have asked me if I ever personally experienced situations like this. The answer, of course, was yes, I had experienced situations similar to their present dilemma. The old adage, “Time is money,” is so true in dentistry when we are confronted with frustrating and costly remakes, not to mention our unhappy patients.

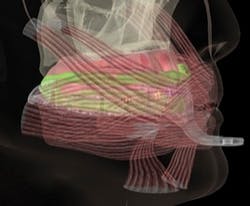

Figure 1

In the world of milled prosthetics, the rules are completely different than in the past. There is virtually no room for error in our impression-making procedures today due to CAD/CAM technologies and high precision restorations. Our success relies, among other things, on two important factors, a precise impression and a precise cast. This has always been the foundation of prosthetic success; however, there is less margin for error than in the past.

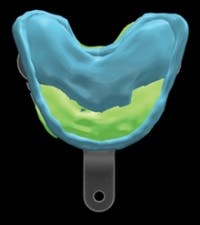

Figure 2

In today’s dentistry, it is vital to make accurate impressions the first time, providing a predictable and precise prosthetic fit. Generally, single-tooth implant impressions are handled very much like routine crown and bridge impressions and have been relatively successful. However, when multiple implants are being restored, especially when providing the fixed and/or milled restorations, a single inaccuracy can easily cost us precious time and money and be extremely stressful.

Generally, if the prosthesis fits the model, then we, the dentists, are held responsible for the nonfitting restorations. In reviewing the various factors of multiple implant impressions, we must also include the accuracy of the final cast.

In this article, I have outlined a verified, precise impression method sequencing the steps in the impressions of multiple, nonparallel implants on a maxillary arch as an example to demonstrate this approach. It is important, however, to understand that this method may initially take longer in making the impression, but is ultimately time saving and less stressful. We all want to have predictable and excellent results; however, we must rethink the process of making extremely accurate impressions when it comes to multiple implants and milled restorations.

Figure 1 shows a maxillary arch with fixed implant impression copings in place.

Figure 2 shows a clear thermoplastic tray (gdit.us) positioned so that the implants are centered in the tray troughs in order to provide adequate spacing of the impression material on all sides of the implant copings.

Figure 3 shows a thin layer of rigid polyvinyl siloxane (PVS) impression material on the palate, around the tissue areas, and directly over the implant copings, which will act as stops. The stops will secure the desired location and placement of the tray as further impression steps are made, and reduce tray movement of the operator’s hand while the material is setting up. Rotational movement of the tray during the setting phase may create inaccuracies.

Figure 4 shows the indentations produced once the PVS stops have set. These stops allow the dentist to go back into the mouth with the impression tray and tactilely know when the impression is seated properly. These stops will also direct the operator’s path of reinsertion, assuring that the tray is fully seated.

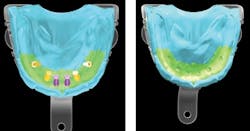

Figures 5 and 6 shows a rigid PVS material placed around the entire peripheral row, while the patient goes to physiological muscle molding movements. This particular procedure finalizes the custom tray and allows the dentist to go in with the final wash and pick up the final detail necessary for the final prosthetic restoration.

Figure 7 demonstrates the custom tray, which has now been filled with a light viscosity on the tissue areas and a rigid viscosity in the areas of the implants. This is then placed into the mouth and once set and removed will allow both the tissue portion and the implant portion to have optimal fit. The rigid viscosities around the implants will decrease movement of the impression copings while the cast is being fabricated.

Figure 8 demonstrates the completed impression and Figure 9 shows the inserted impression copings with the analogs seated firmly into impression sockets. Note that if the impression is inaccurate and/or the impression copings are not placed securely while the cast is being fabricated, an inaccurate final cast will result. This technique described gives the ability to have an intimate fit while having an opportunity to make alterations prior to the final wash to ensure an accurate result.

See you next month. I hope my pleasure in dentistry will also be yours. . . Dr. Joe Massad.

To see Dr. Massad’s video tips, visit www.dentistryIQ.com

Past DE Issues