Dental 3D printing for the technologically challenged

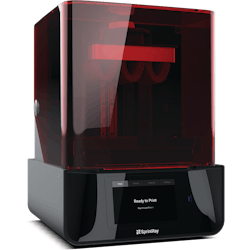

They are everywhere. Those weird-looking R2-D2s in dental suppliers’ showrooms, at dental conventions (remember those?), and in every journal shoved into your mailbox. So what’s the deal with dental 3D printing? You fill the machine with some gray ooze and out pops a slimy object straight out of a Ridley Scott movie. Why should you part with your hard-earned cash in exchange for gaining some serious digital nerd cred? Well, read on! I have made all the mistakes and lost enough money on this, so you don’t have to (figure 1).

When engineers want something to be “dummy proof,” I always know they are talking about me. The years of dentistry, among other things, have shriveled my noodle to the size of an acorn. After the engineers holster their pens in their pocket protectors, dental companies reach out to dentists with way too much time on their hands to beta test their latest gadgets that will “Change the way you do dentistry!”...and they come to me!

Why am I confessing that anything with an “on button” should secure a restraining order against me? Because if you want to implement anything in your practice that is even loosely attached to a computer, it needs to be easy. And when I mean easy, I mean like something your 86-year-old flip phone-using grandmother can handle. So, here is my synopsis on 3D printing for idiots after being an OG veteran for a whopping four years.

Sifting through the alphabet soup

Engineers have big, smart brains. And they use said smart brains to come up with really big words and then abbreviate them to sound all cool and relatable. There are many types of 3D printers; these are the biggies: fused deposition modeling (FDM), digital light processing (DLP), and continuous digital light manufacturing (cDLM). What the heck? Stay tuned; what you need to print will help determine which abbreviation to buy.

FDM is the printer that most uncool people think about when they talk about 3D printing. You can find these in most Best Buy stores. FDMYou may have had experience with thermoplastics, such as making a custom tray or an NTI night guard. The filament is heated to blazing-hot temperatures and forced through a nozzle, like a hot glue gun. The resin is built up in layers, and a model is produced. FDM printers are cool because they do not need postprocessing to remove the goo, as there is none. However, the level of detail in an FDM print is pretty low.

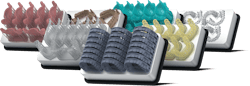

cDLM printers are high-speed and high-accuracy DLP printers. Many can print a dental model in less than 10 minutes. But like Spiderman, with great power comes great price tags. Or something like that. cDLM printers are usually paired with an oxygen or nitrogen tank to help speed up the printing process (figure 6).

In addition to being somewhat challenged in the thinking arena, I am also thrifty (translated dumb and cheap). Most 3D dental printers range in price from $4,200 to about $25,000. There is another class of printers known as LCD (liquid crystal display), which range in priceInstead of a projector, an LCD printer uses a good ol’ phone screen. These screens are low in cost, but, anecdotally, I have found big variations in reliability, accuracy, and ease of use for these printers. So, in a nutshell, pay up and get a decent printer (figure 7).

I hate dentures. There, I said it. I do all the steps. Heat up compound to lip-melting temperatures, and then pull and palpate my patient’s face until they want to call the cops. Then, after the 20 post-op adjustments, it’s still hard to make a buck. A set of digital dentures can be 3D printed for less than $50. Although I confess that I don’t do many, digital dentures have been great for lots of my friends who treat Medicare patients because the reimbursement is low and the cost of making dentures allows these patients to get their teeth (figure 11).

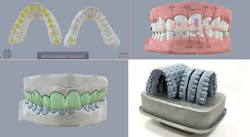

I think one of the coolest uses for 3D printing is DSD (digital smile design), or just name one of the 50 permutations of this concept. BeforeRead also:

3D printing: The technology of now

AUGUST de OLIVEIRA, DDS, graduated from the University of Washington School of Dentistry in 1997 and completed his general practice residency in Los Angeles in 1998. He has been lecturing on 3D technology since 2004 and has written three dental books: Implants Made Easy, Guided Implantology Made Easy, and Dental 3D Printing Made Easy. Dr. de Oliveira lectures for Implant Direct and Dentsply Sirona. He lives and practices in Los Angeles, California.

About the Author

August de Oliveira, DDS

AUGUST de OLIVEIRA, DDS, graduated from the University of Washington School of Dentistry in 1997 and completed his general practice residency in Los Angeles in 1998. He has written three books: Implants Made Easy, Guided Implantology Made Easy, and Dental 3D Printing Made Easy. Dr. de Oliveira lectures for several dental companies, including Implant Direct and Dentsply Sirona. He lives and practices in Los Angeles, California.