TQM: A perfect team for a dentist, his patient, and his lab

by Jean A. Sagara and Arnold G. Rosen, DDS, MBA

Throughout our series on dentist-to-laboratory communications, we have tried to demonstrate that there is a constant, direct, and compelling relationship between outcomes and incomes. This concept certainly is not unique to the dental profession. Indeed, given that most professional and business decisions have economic consequences, good business is always measured by results. For the dentist who strives to offer a strong cosmetic service, the relationship between outcomes and incomes is central to continued success. Moreover, the philosophy of building quality into the process represents a major component of most business school curriculums. Quality is good for business. The actual study and philosophy of a comprehensive approach to management, based upon quality, goes by several names. One that should be familiar to most of us is the term Total Quality Management, or TQM.

TQM was pioneered by Dr. W. Edward Deming in the 20th century. Dr. Deming became famous when the Japanese auto industry applied his techniques in the 1970s and 1980s. As they say, the rest is history. The U.S. automobile industry lost its competitive advantage as the big American car began to be replaced by smaller Japanese vehicles. Dr. Deming's methods have been credited for the ability of the Japanese to produce a superior automobile that was stylish, more fuel-efficient, and better priced.

TQM has one overarching principle: Quality improves and costs decrease through less rework, fewer mistakes, and better use of resources. Dr. Deming believed that doing a task right the first time benefits both the producer and the consumer. He counseled that every aspect of an operation had to be directed at these areas:

- Superior and predictable outcomes

- Increased productivity and profitability

- Increased customer satisfaction

- Increased company pride, goodwill, and loyalty

TQM has its own disciple in dentistry - Dr. James Penna of Monterey, Calif. Dr. Penna calls his adaptation of TQM principles his protocol for "bulletproof success for cosmetic dentistry." His simple system assures dentists better communication with patients and the laboratory, encouraging dentists to try more cosmetic procedures and predictably improving the results of each case.

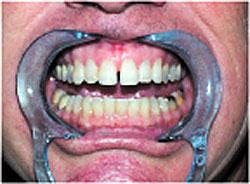

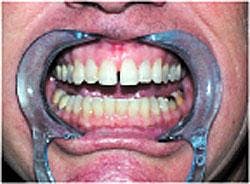

Dr. Penna before

In this article, we are pleased to feature Dr. Penna and his laboratory, Keller Laboratory. Keller is a full-service lab founded in 1946 with locations in St. Louis, Mo.; Kansas City, Mo.; and Louisville, Ky.

Dr. Penna has spent the last 30 years creating a professional environment in his practice that empowers his team, improves patient-to-doctor and laboratory-to-doctor communications, improves quality and productivity, and enhances the quality of life for himself and his employees. His efforts at developing this protocol trace back to his early years in practice when he purchased a DentsplyRegistered system for $25,000 that allowed him to take a photograph and show his patient a "simulation" of the proposed treatment. It made a difference in how he and his patient came to understand the case.

He reflected with us on other positive influences he has had, such as lectures and hands-on training through PAC Live™ and guidance from his mentor, Dr. Robert Hughes, from Everett, Wash. Dr. Penna cites the extraordinary support and team relationship he has developed with Keller Laboratory over the years as contributing to his success.

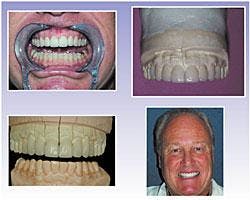

Let's review a case that illustrates Dr. Penna's TQM approach. What makes this case particularly interesting is that he is the patient! His mentor, Dr. Hughes, is the dentist/operator, and Keller Laboratory provided the technical expertise in planning and fabricating his prosthesis.

The first point we must stress is key: Dr. Penna takes immediate responsibility for the outcome of his cases through a protocol that engages the patient in the program, enlists and empowers the team in the planning and treatment process, and works from the beginning to set expectations with the lab. Much like Dr. Deming's original concept, quality and teamwork are the hallmarks of his methodology.

Here is Dr. Penna's "bulletproof plan":

- Engage the patient in the process by taking digital images and creating a simulation that responds to the patient's input.

- Take diagnostic casts for a detailed diagnostic wax-up to match the image.

- Send models and images to the lab for a detailed diagnostic wax-up.

- After the lab completes the wax-up - but before it is returned to Dr. Penna - the lab sends a digital photo of the wax-up for the doctor's approval or modification before completion.

- After tooth preparation, Dr. Penna uses the detailed wax-up to fabricate a temporary prosthesis for the patient.

- Encourage the patient to talk freely to family and friends about the temporary restoration so that he or she may benefit from their feedback.

- Take new images and models of the temporary restoration. If changes are necessary as a result of the patient's "trial" run, forward this information to the lab before the case is

- Have the lab make a digital image of the final restoration for comparison to the approved temporaries so Dr. Penna can approve the result before the case is shipped.

We spoke to Larry Zenk about his views on this case. Larry has 26 years of experience in the laboratory industry. Currently vice president of Keller Laboratory, he is responsible for professional development and key-account management. Larry and Keller Laboratory participate at PAC Live™ Functional Anterior Esthetic Courses, where they first met Dr. Penna and his team.

Initially, Dr. Penna communicated through traditional means - handwritten prescriptions, phone calls, and the occasional photo. Shortly after receiving a few surprises, he began using cosmetic images to describe patients' expectations more accurately and to request diagnostic wax-ups that would match those images. The next step in this evolution was when Dr. Penna requested that photos of the wax-up be sent to him for approval. Finally, he requested that the wax-ups not only match his imaged case, but also that the lab photograph the final porcelain results, side by side with his study model of the diagnostic wax-up.

Larry enthusiastically supports Dr. Penna's approach, saying that there is no doubt that cosmetic imaging, diagnostic wax-ups, and visual communication significantly increase the chances for success. This approach means there will be fewer remakes and fewer reworks, which translates to better outcomes, higher margins, higher productivity, and more opportunity for word-of-mouth referrals for both the lab and the dentist. Many labs report that they remake between 5 and 8 percent of cases due to errors in process, miscommunication, or results that don't meet expectations. The cost of such remakes on smile-design cases can be very high in terms of patient confidence and doctor satisfaction. Dr. Penna's TQM process virtually eliminates most of the causes for rework.

Larry shares, "Dr. Penna has one of the lowest remake percentages of virtually anybody I work with… To achieve our shared success on cases, we spend a little more time communicating than is usual. Because of our success, however, we don't have to review failures. We don't debate paying for remakes, because there aren't any to discuss. That allows us more time to plan other cases and to grow our businesses together."

Dr. Penna will tell you that abdicating responsibility for your case to the lab is a mistake. He does not rush his cases, nor does he rush his lab. He understands that the first link is between the patient and the doctor. Frequently, Dr. Penna points out, the patient's expectations are different from the doctor's at the beginning. It is important to work to get the right look so you can meet your patient's expectations. How you communicate those expectations to the lab is the next challenge. Digital images have facilitated this exchange and made dentist-to-lab communication easier.

Does Dr. Penna's "bulletproof plan" take more time by building all of those TQM checks and balances into the process? He says, "My time is probably not more than 30 minutes, and my assistant's time might be up to two hours ... We do a custom work-up with the patient, detailing color, shape, and length and rounding corners. The patients tell the assistants more than they tell the doctor. The change in my team's attitude is incredible. They get so excited about these cases. Becoming a part of this protocol has allowed them to develop additional skills."

Dr. Penna tells us that interactive communication with his patient and his lab is critical to a successful outcome. This sequential dialogue with the lab - the checking before a final restoration is completed, as well as the full engagement of the patient in the process - is at the heart of his "bulletproof plan." Clearly, he understands TQM's essence: getting it right the first time. Digital images and cosmetic imaging provide a quality media for planning and integrating quality assurance into the treatment protocol.

Total Quality Management - a time-proven protocol - works as a method to improve communications among all parties - the dentist, the patient, and the lab. For every case Dr. Penna does, he gets at least one solid referral. His conversion rate for patient case acceptance is nearly 100 percent. And, just as important, his hourly productivity was at $600 previously; now, it is more than $1,000 per hour. As the saying goes, "If something is worth doing, it is worth doing well." Effective communication with patients and labs matters. For Dr. Penna and his team, quality methods are "bulletproof." Good quality is indeed good business.

This article was developed with the cooperation of Dr. James Penna and his team and Larry Zenk at Keller Laboratories, Inc. Dr. Penna can be reached via email at [email protected], and Zenk can be contacted at Keller Laboratories at (888) 919-7577, Ext. 4037, or email [email protected] and visit www.kellerlab.com.